Although 3D printing has was first developed in 1984, established companies and trendy start-ups alike have just begun experimenting with the technology over the past couple of years. This is mainly due to the fact that recent advancements in the 3D printing space have made it much more cost-effective than ever. In fact, 3D printing is now so cheap that companies are manufacturing things like pens, figurines, and household tools with 3D printing technology. Here’s how future of 3D printing in healthcare is:

Medical science firms have also spent the last few years trying to figure out how to utilize 3D printers to lower health care costs and treat sick or injured patients. Although 3D printing-oriented advancements in the medical sphere have been fairly moderate thus far, using the technology to solve all sorts of medical quandaries in the future is an achievable dream.

Let’s take a look at future of 3d printing in healthcare

Using 3D Printing to Advance Surgical Procedures

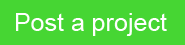

According to the U.S. Food & Drug Administration, 3D printers are already being relied on to manufacture medical equipment and surgical devices that can match a patient’s unique body type or anatomical requirements. Creating this specialized surgical equipment helps doctors treat the unique needs of their patients more effectively and efficiently.

At the moment, 3D printing has already been used to build extremely complex surgical instruments at a cheaper cost than creating those same instruments via conventional manufacturing techniques. Naturally, this helps to chip away at rising medical costs in the United States.

There is currently experimentation with utilizing 3D printers to manufacture medical equipment and surgical devices that can be designed to specifically fit certain patient’s anatomical requirements.

Using 3D Printing to Create Body Parts

You have no doubt seen the headlines flash across your television or computer screen — companies are now creating on-demand products in real-time thanks to innovations in the 3D printing space. Since 2014 or so, clothing companies, jewelers, and manufacturers have experimented with creating things like jewelry, shoes, and t-shirts from 3D printing methods.

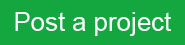

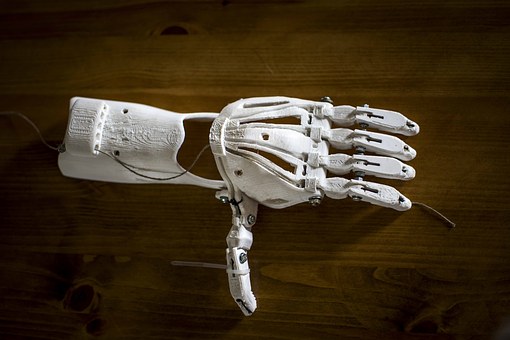

What most people are not aware of, however, is that medical professionals are also using 3D printing as a way to create new body parts for patients. Amazingly, medical technology firms have used printing methods to generate new skin for burn victims, as well as new airway splint implants for toddlers and babies who are suffering from various respiratory issues.

As 3D printing technology continues to develop, doctors are hoping to use 3D printing to create more complex implants for ailing patients. Similarly, doctors want to eventually utilize 3D printing to create new hands, feet, legs, noses, and eyes for people. Forward-thinking pathologists are also trying to figure how use 3D prosthetic organs to fight infections and disease.

Doctors and scientists are working to perfect 3D printing appendages, such as hands, ears, etc., for advanced prosthetic use.

The possibilities of using printing technology to improve cosmetic surgical procedures — or even improve the capabilities of the human body — are also endless. For example, scientists at Princeton are currently developing a so-called “bionic” ear from 3D printing technology that is capable of recognizing radio frequencies that the human ear cannot hear.

In terms of plastic surgery, creating the perfect cheek, nose, or set of eyes will help plastic surgeons meet the demands of their clientele, most of whom want to look and feel younger.

The Future of 3D Printing in Medicine and Beyond

Although we are still years away from being able to reliably create new body parts and organs from 3D printers, the technology will continue to revolutionize how doctors and surgeons treat their patients.

3D printing will also have a huge effect on industries outside of the medical sphere, too. It’s interesting to think that so many of the things we need — whether a shirt, vehicle, or brand new organ, will eventually be created via 3D printers.

——

Need help with your research or business project? Consult a freelance scientist on Kolabtree.